Shell and Tube Condensers

Price 100000.00 INR/ Unit

MOQ : 1 Unit

Shell and Tube Condensers Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- MUMBAI

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 5 Days

- Packaging Details

- SKID Mounted

- Main Domestic Market

- All India

About Shell and Tube Condensers

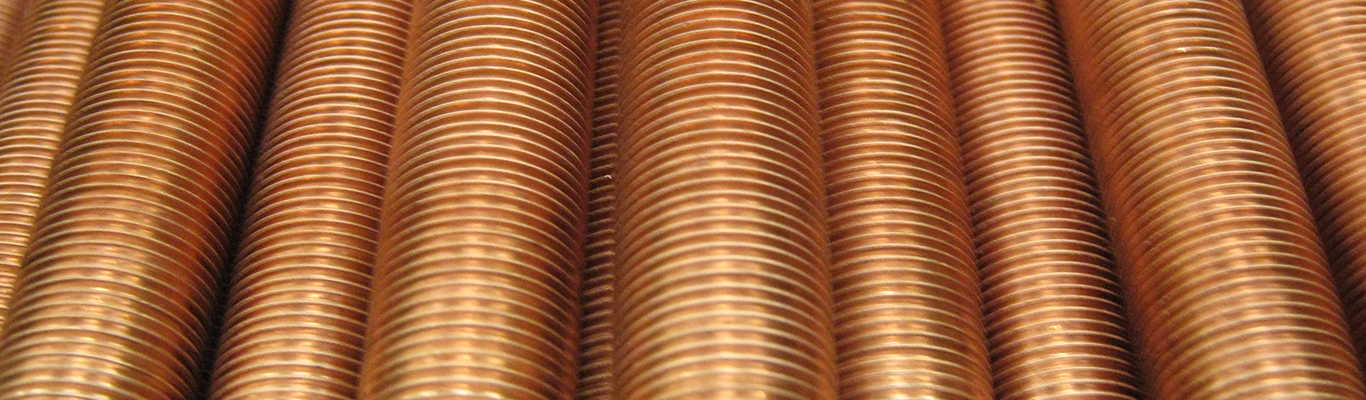

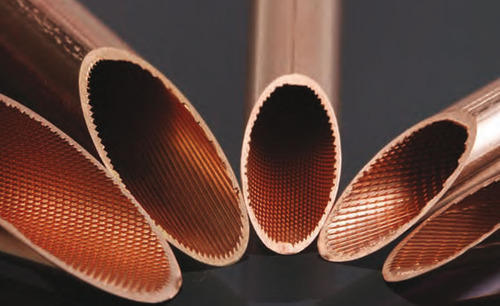

Shell and Tube Condensers Features: Multiple Refrigerant Options Available - Ammonia, R22, R404A, R407C, R134a etc.Multiple Shell Material Options Available - Mild Steel, SS304, SS316L, Cupro NickelMultiple Tube Options Available - TATA Boiler Tubes, Seamless Boiler Tubes, SS304, SS316L, Copper, Cupro NickelIntegrally Finned Copper Tubes for Added EfficiencyDesigned with CAD and Heat Exchanger Softwares.Pneumatically and Hydraulically TestedHinged Bonnet Design for Easy MaintenanceThicker TubesElectronically Expanded Tubes for Precision5 Years Unconditional Warranty Technical Specifications Surface Treatment Powder Coated Usage/Application Power Generation, Hydraulic and Industrial Process, Pharmaceutical industry, etc Material Mild Steel and also available in Stainless Steel and Galvanized Iron Brand Singhsons Outlet Temperature -40 to 120 Deg C Medium Used Air, Water, etcFAQs of Shell and Tube Condensers:

Q: What styles are available for the Shell and Tube Condensers?

A: The Shell and Tube Condensers are available in a single-temperature style.Q: What materials are used to manufacture the Shell and Tube Condensers?

A: The Shell and Tube Condensers are made from MS (Mild Steel), SS (Stainless Steel), Copper, and Cupro-Nickel.Q: What refrigerants are compatible with Shell and Tube Condensers?

A: The Shell and Tube Condensers are compatible with Ammonia, R22, R404A, R407C, R508b, R134a, and others.Q: Can Shell and Tube Condensers handle multiple refrigerants simultaneously?

A: No, the Shell and Tube Condensers are designed for single-temperature operation, meaning they work with one refrigerant at a time.Q: Are Shell and Tube Condensers suitable for both industrial and commercial applications?

A: Yes, the robust design and compatibility with various refrigerants make Shell and Tube Condensers suitable for numerous industrial and commercial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Shell and Tube Heat Exchangers Category

Shell and Tube Chillers

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Style : SingleTemperature

Temperature : 80 Celsius (oC)

Material : MS/ SS304/ SS316L/ Copper/ Cupro Nickel

Type : Shell and Tube

We are mainly export our products in Middle East and Africa.

We want Bulk Inquires.

We want Bulk Inquires.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese