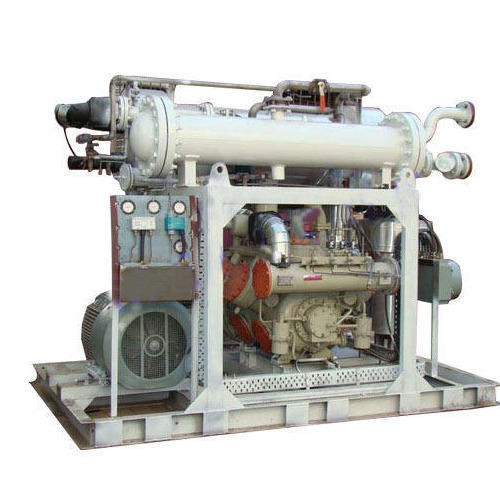

Ice Bank Tank Systems

Price 500000 INR/ Unit

Ice Bank Tank Systems Specification

- Application

- Milk Chilling, Beverage Cooling, Process Chilling, Dairy Industry

- Air Flow

- Optimized Through Ducted Vents

- Motor

- Heavy Duty, Low Noise Electric Motor

- Material

- Stainless Steel SS304

- Condition

- New

- Type

- Ice Bank Tank System

- Dimension (L*W*H)

- Customized as per Requirement

- Power Supply

- 3 Phase, 50 Hz

- Cooling Type

- Indirect / Static Cooling

- Nozzle Material

- Food Grade SS304

- Cooling Coil Material

- Stainless Steel 304

- Water Flowing Rate

- 3000 LPH

- Water Pump Motor

- Crompton or Equivalent, 1 HP

- Noise Control

- Below 65 dB

Ice Bank Tank Systems Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 1-2 Week

About Ice Bank Tank Systems

Backed with dexterous team of professionals, we are affianced in offering highly efficient Ice Bank Tank Systems that are available in various capacities and model to meet the diverse needs of the clients. These systems are manufactured using supreme quality components that are procured from the trustworthy vendors of the market. Offered tank systems are used in dairy, chilled milk tank, plate heat exchanger etc. The offered Ice Bank Tank Systems are known for their sturdy construction, easy installation, low maintenance and long service life.

Advanced Cooling Performance

Engineered for efficiency, this Ice Bank Tank System achieves rapid and effective cooling through indirect or static methods. Its robust motor and ducted vents facilitate uniform air distribution, ensuring optimal temperature control vital for dairy and beverage processing.

Durable Stainless Steel Construction

Constructed with food-grade SS304 steel for both nozzle and cooling coils, this tank promises longevity, high hygiene standards, and minimal maintenance. Its customized dimensions allow seamless integration into various industrial setups.

Low Noise Operations

Specially designed for noise levels below 65 dB, the heavy-duty electric motor ensures a quiet working environment without sacrificing performance, creating a more comfortable atmosphere for industrial applications.

FAQs of Ice Bank Tank Systems:

Q: How does the Ice Bank Tank System optimize air flow?

A: The system uses ducted vents strategically placed to enhance air circulation, ensuring even cooling and improved energy efficiency during beverage and milk chilling processes.Q: What materials are used to construct the Ice Bank Tank System?

A: All contact surfaces, including the nozzle and cooling coil, are made of food-grade Stainless Steel SS304, providing durability and resisting corrosion, which ensures hygienic operation for food and dairy industry use.Q: When should I use an Ice Bank Tank System in my workflow?

A: This system is recommended whenever consistent, large-capacity cooling is requiredfor example, in the processing stages of dairy, beverage production, and industrial chilling applications where hygiene and temperature control are crucial.Q: Where can the Ice Bank Tank System be installed?

A: Thanks to its customizable dimensions and robust build, the system can be installed in dairy plants, beverage factories, or any industrial location in India as per the specific space and process requirements.Q: What is the process of chilling with this system?

A: Water flows at a rate of 3,000 LPH over cooling coils made from SS304, absorbing heat from products indirectly. The heavy-duty motor maintains low noise, while the water pump ensures continuous circulation for effective chilling.Q: How does the Ice Bank Tank System benefit dairy and beverage industries?

A: It provides reliable temperature regulation and hygiene with its indirect cooling technique, food-grade materials, and noise control, supporting product quality and compliance with industry standards.Q: What type of power supply does the Ice Bank Tank System require?

A: It is designed to operate on a 3-phase, 50 Hz power supply, suitable for industrial environments and ensuring steady performance during continuous operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chilling Plants Category

Water Chilling Plants

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Compressor : Reciprocating, Scroll, Screw Compressor Options Available

Material : Concrete

Application : Concrete Cooling

Type : Water Cooled/ Air Cooled

Screw Chillers

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Compressor : J & E Hall Screw/ Howden/ Mycom/ Bitzer/ Snow Key etc.

Material : Metal

Application : Pharmaceutical, Chemical, Dairy, Brewery, Process Cooling Industry

Type : Automatic

Reciprocating Compressor Chilling Plants

Price 700000 INR / Unit

Minimum Order Quantity : 1 Unit

Compressor : Kirloskar/ Mycom/ Bitzer/ Copeland etc.

Material : Metal

Application : Pharmaceutical, Chemical, Dairy, Breweries, Bakeries, Process Chilling

Type : Open/ Semi Hermetic

Air Chilling Plants

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Compressor : Kirloskar/ Mycom/ J&E Hall/ Bitzer/ Emerson etc.

Material : Metal

Application : Oleochemichal, Chemicals, Pharmaceutical Industry.

We want Bulk Inquires.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese